CORDÓN DE CONEXIÓN DE FIBRA ÓPTICA

Latiguillo De Fibra óptica SC LC

Latiguillo De Fibra óptica SC LC

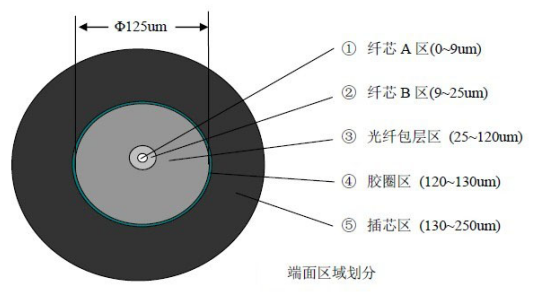

1. Requisito de cara final:

1.1 Equipo de prueba: 400 × lupa, pantalla

1.2 Estándar de prueba:

Geographic range | Defect description | End face detection standard |

Core A area | Scratch, gap | Not allowed |

Holes, spots | Not allowed | |

Dirty, foreign matter | Not allowed | |

‚ Core B area | Scratch, gap | Not allowed |

Holes, spots | Not allowed | |

Dirty, foreign matter | Not allowed | |

ƒ Optical cladding zone | Scratch, gap | Width ≦ 3um has one |

Holes, spots | Diameter ≦ 3um has one | |

Dirty, foreign matter | It is not allowed to be dirty. If it cannot be wiped, it is judged by holes. | |

④ Apron area | Scratch, gap | Width ≦ 20um has two |

Holes, spots | Diameter ≦ 20um has two | |

Dirty, foreign matter | It is not allowed to be dirty. If it cannot be wiped, it is judged by holes. | |

⑤ Ferrule area | Scratch, gap | Width ≦ 30um has two |

Holes, spots | Diameter ≦ 30um has two | |

Dirty, foreign matter | It is not allowed to be dirty. If it cannot be wiped, it is judged by holes. | |

Note: No cracks are allowed in the above areas, and the total defects are no more than 3 | ||

Figure 1

1.3 End face icon:

2. Standard test:

Product name | Insertion loss(IL) | Return loss(RL) | |

PC | SM | 0.25dm@1310um | 50dB@1310um |

MM | 0.25dm@850um | 45dB@850um | |

APC | SM | 0.25dm@1310um | 60dB@1310um |

Performance

Specification | |||||

Item | Unit | SM | MM | ||

SC/PC SC/UPC SC/APC | SC/PC | ||||

Insertion Loss | dB | ≤0.20 | |||

Max. Insertion Loss | dB | ≤0.30 | |||

Repeatability | dB | ≤0.10 | |||

Changeability | dB | ≤0.20 | |||

Return Loss | dB | 45 | 50 | 60 | |

Operation Temperature | ℃ | -25 ~ +70 | |||

Storage Temperature | ℃ | -40 ~ +85 | |||

Fiber type | um | 9/125 | 50/125,62.5/125 | ||

Core number | single or dual fiber | ||||

Durability | >1000 times | ||||

Industry Standard | Bellcore TA-NWT-001209 | ||||

2. 3D standard:

Pin outer diameter | Radius of curvature | Vertex offset | Light solder height | angle(。) | |

Ф2.5 | PC UPC type | 10~25 | ≤50 | -100~+50 | ------ |

APC type | 5~15 | ≤50 | -100~+50 | 8士0.3 | |

Ф1.25 | PC UPC type | 7~25 | ≤50 | -100~+50 | ------ |

APC type | 5~15 | ≤50 | -100~+50 | 8士0.3 | |

Note: In the numerical value of the column height, the positive sign indicates that the light solder is convex, and the negative sign indicates the light solder recess. ‚ PC pass rate is 70%, APC pass rate is 60%. | |||||

Figure 2

3. Paquete:

4.1 Bobinado:

ф1.8/2.0/3.0mm El cable óptico se enrolla dos veces alrededor de un metro, se envuelve con alambre blanco, se enreda con 5 metros y se retuerce dos veces y luego se anuda.

‚ ф0.9mm El cable óptico se enrolla dos veces alrededor de un metro y se usa el tubo serpenteante. (El tamaño del tubo serpenteante está determinado por la longitud del cable y la especificación es de 2,0/4,0 mm.

4.2 Tamaño de la bolsa:

Ф0.9 pigtail y ≦3M jumper con bolsa autosellante de 18×18cm (3.0 duplex 3M con bolsa ziplock de 22×22cm)

‚ Bolsa ziplock de 22×22 cm para cable de ф1.8/2.0/3.0 mm de 3M o más

ƒ Todas las bolsas ziplock requieren bordes blancos y las bolsas deben perforarse. Cada lote de agujeros perforados debe estar en la misma posición.

4.3 Embalaje:

Ф0.9 se coloca en una bolsa autoadhesiva de 18 × 18 cm de tamaño por 1 pieza y se adjunta la etiqueta (la etiqueta se adjunta en el medio de la bolsa con cierre hermético)

Cada bolsa de 10 piezas se empaqueta en una bolsa ziplock de 22 × 22 cm y se coloca un cojín en los lados superior e inferior de la caja interior para protegerla.