Fiber Optic drop CABLE

GJXFH-1B Fiber Optic Drop Cable-Round

Cable Specification

2.1 Introduction

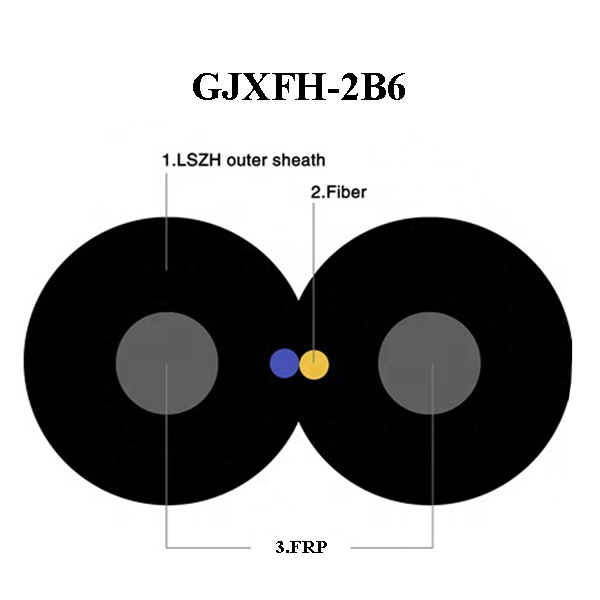

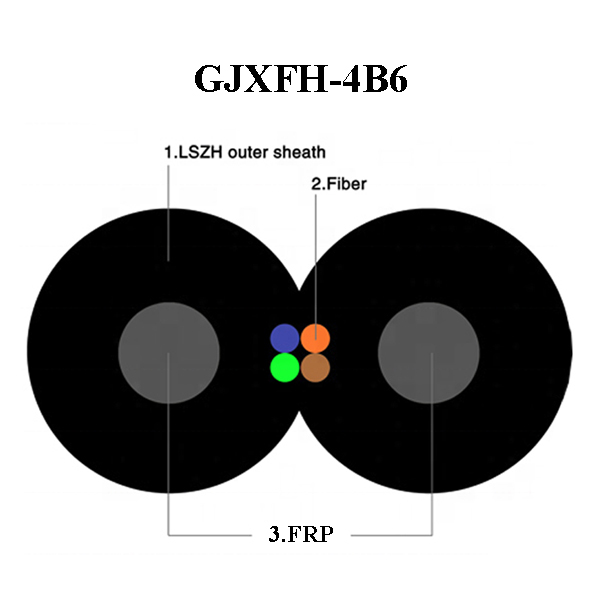

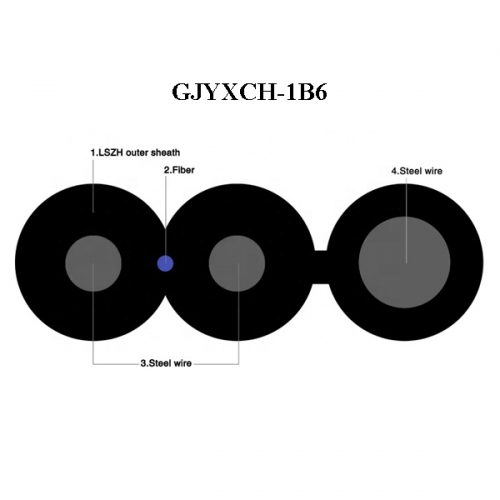

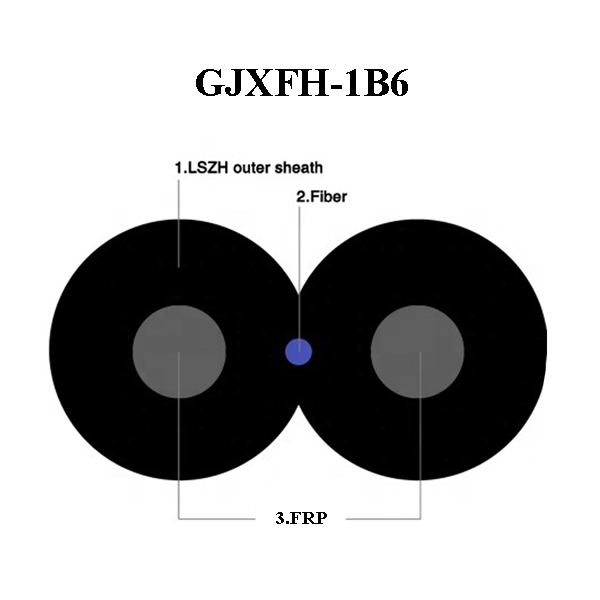

The optical fiber unit is positioned in the center. Two parallel fiber reinforced plastics (KFRP) are placed at two sides. A steel wire as the additional strength member is also applied. Then the cable is completed with black LSZH sheath.

2.2 Fiber color code

Fiber color starts from No. 1 Blue.

2.3 Optical fiber type and properties

Item | Unit | Specification | |

G. 657A2 | |||

Mode field diameter | 1310nm | mm | 8.6 ± 0.4 |

Cladding diameter | mm | 125.0 ± 0.7 | |

Cladding non-circularity | % | £1.0 | |

Core concentricity error | mm | £0.5 | |

Coating diameter | mm | 245 ± 5 | |

Coating/cladding concentricity error | mm | £12 | |

Cable cut-off wavelength | nm | £ 1260 | |

Attenuation Coefficient | 1310nm | dB/km | £0.35 |

1550nm | dB/km | £0.21 | |

Macro-bend loss (1 turn,7.5mm radius) | 1550nm | dB/km | £0.5 |

1625nm | dB/km | £1.0 | |

Proof stress level | kpsi | ≥100 | |

Other parameters meet standard ITU-T G.657

2.4 Cable structure and parameter

Item | Parameters | |

No. of fibers | count | 1 |

Strength member | Diameter | 0.58 mm |

Material | KFRP | |

Messenger wire | Diameter | 1.0 mm |

Material | Steel wire | |

Outer jacket | Diameter | 5.2(±0.2)*2.0(±0.1) mm |

Material | LSZH | |

Color | Black | |

Tensile performance | Short term | 600 N |

Long term | 300 N | |

Crush | Short term | 2200 N/100mm |

Long term | ||

Cable attenuation | ≦ 0.38dB/km at 1310nm, ≦ 0.25 dB/km at 1550nm | |

Cable weight (Approx.) | 18.3 kg/km | |

3. Characteristic of Optical Cable

3.1 Min. bending radius for installation (Without messenger wire)

Static: 15

Dynamic: 30

3.2 Application temperature range

Operation: - 20℃ ~ +70℃

Installation: -20℃ ~ +70℃

Storage/transportation: - 20℃ ~ +70℃

3.3 Main mechanical & environmental performance test

Item | Test Method | Acceptance Condition |

Tensile Strength IEC 60794-1-2-E1 | - Load: Short term tension - Length of cable: ≥ 50m - Load time: 1min | - Fiber strain ≤ 0.4% - No fiber breakage and no sheath damage. |

Crush Test IEC 60794-1-2-E3 | - Load: Short term crush - Load time: 1min | - No fiber breakage and no sheath damage. |

Impact Test IEC 60794-1-2-E4 | - Points of impact: 3 - Times of per point: 1 - Impact energy: 1J | - No fiber breakage and no sheath damage. |

Repeated Bending IEC 60794-1-2-E6 | - Bending radius: 30x H - No. of cycle: 300 -Load: 20N | - Fiber additional attenuation should be no more than 0.4dB; -There shall be no damage to the cable elements under visual inspection. |

Torsion IEC 60794-1-2-E7 | - Length: 1m - Twist angle: ±180° - No. of cycle: 20 | - No fiber breakage and no sheath damage. |

Temperature Cycling IEC 60794-1-2-F1 | -Temperature: -20oC~+70oC - Time of each step: 8h - Number of cycle: 2 | - Fiber additional attenuation should be ≤ 0.4dB/km; - There shall be no damage to the cable elements under visual inspection. |