Fiber Optic drop CABLE

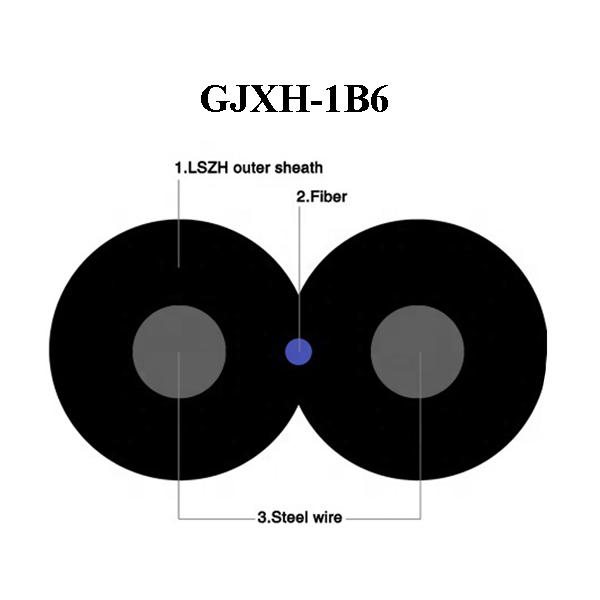

Indoor Drop Cable GJXH-1B6

1. Cable Specification

1.1 Introduction

The optical fiber unit is positioned in the center. Two parallel steel wire are placed at two sides.

Then the cable is completed with black or color LSZH sheath.

1.2 Fiber color code

Fiber color starts from No. 1 Blue.

1.3 Optical fiber type and properties

Item | Unit | Specification | |

G. 657A | |||

Mode field diameter | 1310nm | mm | 8.6 ± 0.4 |

Cladding diameter | mm | 125.0 ± 0.7 | |

Cladding non-circularity | % | £1.0 | |

Core concentricity error | mm | £0.5 | |

Coating diameter | mm | 245 ± 5 | |

Coating/cladding concentricity error | mm | £12 | |

Cable cut-off wavelength | nm | £ 1260 | |

Attenuation Coefficient | 1310nm | dB/km | £0.35 |

1550nm | dB/km | £0.21 | |

Macro-bend loss (1 turn,7.5mm radius) | 1550nm | dB/km | £0.5 |

1625nm | dB/km | £1.0 | |

Proof stress level | kpsi | ≥100 | |

Other parameters meet standard ITU-T G.657

1.4 Cable structure and parameter

Item | Parameters | |

No. of fibers | count | 1 |

Strength member | Diameter | 0.45 mm |

Material | Steel wire | |

Outer jacket | Diameter | 3.0(±0.1)*2.0(±0.1) mm |

Material | LSZH | |

Color | Black | |

Tensile performance | Short term | 200 N |

Long term | 100 N | |

Crush | Short term | 2200 N/100mm |

Long term | 1100 N/100mm | |

Cable attenuation | ||

Cable weight (Approx.) | 10.0 kg/km | |

2. Characteristic of Optical Cable

2.1 Min. bending radius for installation

Static: 15

Dynamic: 30

2.2 Application temperature range

Operation: - 20℃ ~ +70℃

Installation: -20℃ ~ +70℃

Storage/transportation: - 20℃ ~ +70℃

2.3 Main mechanical & environmental performance test

Item | Test Method | Acceptance Condition |

Tensile Strength IEC 60794-1-2-E1 | - Load: Short term tension - Length of cable: ≥ 50m - Load time: 1min | - Fiber strain ≤ 0.4% - No fiber breakage and no sheath damage. |

Crush Test IEC 60794-1-2-E3 | - Load: Short term crush - Load time: 1min | - No fiber breakage and no sheath damage. |

Impact Test IEC 60794-1-2-E4 | - Points of impact: 3 - Times of per point: 1 - Impact energy: 1J | - No fiber breakage and no sheath damage. |

Repeated Bending IEC 60794-1-2-E6 | - Bending radius: 30x H - No. of cycle: 300 - Load: 20N | - Fiber additional attenuation should be no more than 0.4dB; - There shall be no damage to the cable elements under visual inspection. |

Torsion IEC 60794-1-2-E7 | - Length: 1m - Twist angle: ±180° - No. of cycle: 20 | - No fiber breakage and no sheath damage. |

Temperature Cycling IEC 60794-1-2-F1 | -Temperature: -20oC~+70oC - Time of each step: 8h - Number of cycle: 2 | - Fiber additional attenuation should be ≤ 0.4dB/km; - There shall be no damage to the cable elements under visual inspection. |