DOME CLOSURE

CT-D01H FIBER OPTIC 48 CORE SPLICE CLOSURE

Fiber Optic Splice Closure

Overviewoptical splice closures are used to distribute, splice, and store the outdoor optical cables which enter and exit from the ends of the closure. There are two connection ways: direct connection and splitting connection. They are applicable to situations such as overhead, man-well of pipeline, embedded situation etc. Comparing with terminal box, the closure requires much stricter requirement of seal. Sealing ring and air valve are required for closure, but that are not necessary for terminal box. Features

|

Heat shrink seal Type |

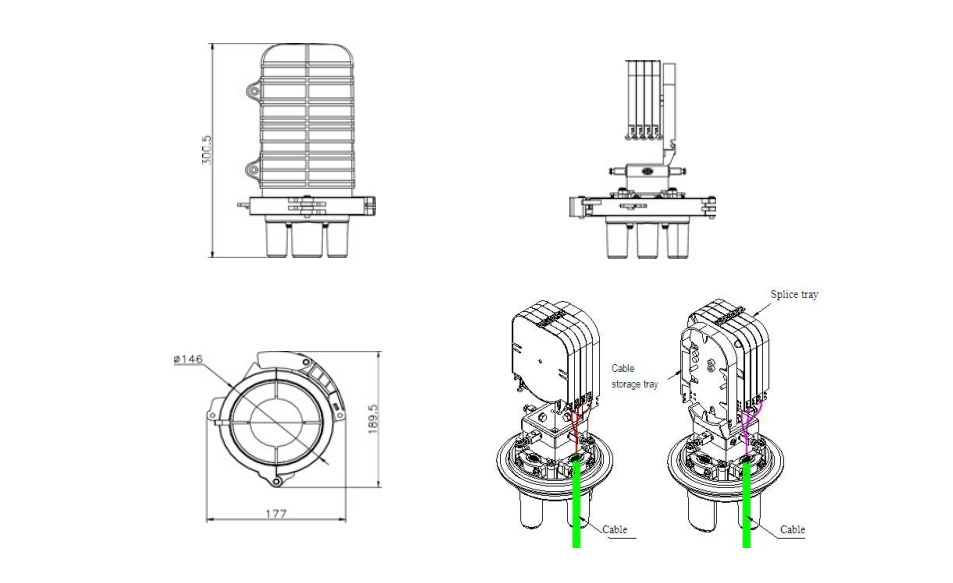

Products View

Dimensions and Capability

| Dimensions (D*H) : | 300mm*120mm |

| Max Capacity: | 48 Cores |

| Number of Cable Entrance/Exit: | 1:3 |

| Diameter of Cable: | 3 small round ports(21mm) and 1 large oval port(34mm) |

Operation Conditions

| Temperature: | -40℃~+60℃ |

| Humidity: | ≤95% (at 40℃) |

Air Pressure: | 70kPa ~106kPa |

Technical Specifications

Seal performance: after the box is sealed, inflate to 100kPa inwards (inflation only apply to the models with the air hole), and then soak it in the water of normatemperature, after 15 minutes of steady observation, there is no bubble to overflow.

Insulation resistance: the insulation resistance between the metal work piece and the earth is greater than 20kMΩ.

Pressurization: there is no breakdown or flashover under 15kVdc/1min between the metal work piece and the earth.

The curvature radius of the fiber 40mm, without extra loss inside the splice tray.

It can bear the axial tensile strength no less than 1000N.

Lifetime: 25 years.

Other performances are all in accordance with the requirement of standard YD/T814-1998.